Introduction to Hybrid Pipe and also Tube Benders!

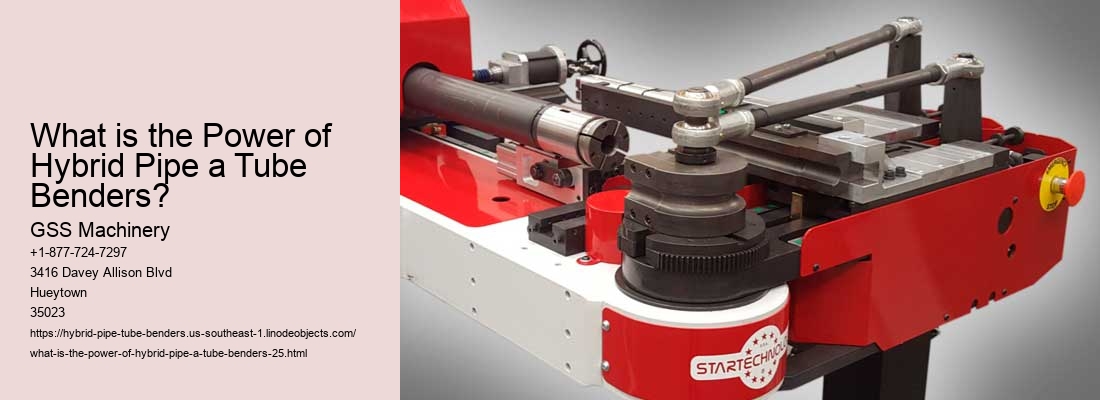

Pipe and tube benders are tools made use of in metalworking to develop a pipe or tube right into a preferred shape. They can be found in 2 kinds: manual and also hydraulic, now there is an also far better alternative on the marketplace - hybrid pipe and also tube benders! These revolutionary machines integrate the very best of both globes, offering outstanding accuracy with increased performance.

Unlike hands-on designs, hybrid benders are furnished with an electric motor that gives even more power than human stamina can supply. This implies that tighter curves can be attained with much less effort from the driver. In addition, these equipments include automatic backgauging systems which help make sure exact results whenever. Yet what truly sets them apart is their capacity to change in between different bending modes according to your needs - making them extremely versatile for any kind of sort of job.

Moreover, hybrid benders are unbelievably very easy to use many thanks to their easy to use control panels. With plainly identified buttons and handles, even newbie individuals will certainly have no problem navigating through the numerous settings. Furthermore, they also feature numerous safety features such as emergency situation quits and also safety shields that will protect you from any kind of potential crashes.

In conclusion, hybrid pipe and also tube benders offer unsurpassable efficiency at a cost effective rate point - making them optimal for experts searching for a trusted equipment that won'' t break the bank. As a result, if you'' re in need of effective bending services without jeopardizing on quality, then this may just be the ideal device for you!

In conclusion, Hybrid Pipe & & Tube Benders offer great benefits when it comes to precision and also ease while being much more secure than typical techniques as a result of its integrated safety and security functions. This makes it an excellent choice for anyone trying to find a dependable device at an obtainable price point!

Hybrid pipe and tube benders supply many benefits! They integrate the best attributes of both hands-on as well as computerized flexing makers, making them a functional device for any project. (Tightenings: They'' re)From increased safety and security to enhanced accuracy, right here are several of the benefits of using these powerful

equipments. First, hybrid benders are much more secure than traditional techniques. Hand-operated bending can be harmful because of the possibility for pinch points or various other threats associated with sharp bends. By comparison, a hybrid device is created to prevent such risks while still generating limited curves without sacrificing accuracy. And also, given that they put on'' t require manual work, it removes the need for staff members to work in harmful problems.

In addition, hybrid benders can develop complicated curves effortlessly! The mix of automated and also manual controls enables customers to change bend angles promptly and precisely; this increases productivity substantially contrasted to standard techniques. Additionally, because they wear'' t need additional tools or components, there'' s no need for—extra configuration time-- just fill your product and begin flexing

! Furthermore, hybrid pipe and also tube benders offer superb precision also! Unlike hands-on makers that rely on human vision alone to evaluate precision levels, crossbreeds utilize sophisticated sensors that discover even little incongruities in a bend'' s angle or distance. This makes certain consistent results every time you utilize your equipment—-- a must-have attribute when servicing jobs with precise specifications!

Lastly yet significantly (Interjection: Wow!), hybrids likewise save money in regards to upkeep prices. Conventional designs may require regular calibrations or changes that can bring about pricey repair work in the long run; nevertheless, hybrid makers are normally much more reputable and also durable than their equivalents—-- so you won'' t need to stress over investing additional cash on maintenance!

Overall (Shift expression), there are countless benefits of utilizing hybrid pipe and tube benders over traditional ones! From boosted safety to improved accuracy and price savings in upkeep prices—-- these flexible tools provide an invaluable source for any type of task needing specific bends with marginal initiative included.

Hybrid pipe as well as tube benders are a sort of device that allows users to bend pipelines and tubes quickly. They can be found in various sizes and shapes, making them optimal for various kinds of jobs. With hybrid benders, you can produce curves, angles, circles as well as even more with marginal effort (and also also without using any special devices). You simply require to feed the tube or pipe right into the device'' s flexing head and then permit the equipment to do the rest!

There are a number of sorts of hybrid benders readily available out there. The most typical type is an electric-hydraulic bender which makes use of hydraulic pressure to help bend steel sheets securely and successfully. This type of bender additionally features a motorized power source that helps accelerate flexing procedure substantially. One more popular alternative is a manual-hydraulic bender which calls for manual operation but still produces exceptional outcomes. It has a hand wheel operated hydraulic pump that helps regulate the pressure used on the product while it'' s being curved. (Both types call for marginal set-up time.)

Additionally, there are some more specialized designs such as semi-automatic or programmable benders which permit individuals to preprogram particular bends before starting the procedure. These makers are terrific for bigger scale manufacturing work as they supply repeatable accuracy every time! In addition, there is an automated rotating draw bender which benefits lengthy straight bends. Lastly, there is an induction home heating pipe bender which utilizes warmth generated by electric present rather than mechanical pressure to make limited bends in ferrous steels! Wow!

Overall, hybrid pipe & & tube benders provide tremendous ease when it comes to developing complex shapes from metal materials rapidly as well as efficiently without compromising quality. And also, their large range of functions makes them suitable for lots of types of tasks, ranging from tiny DIY tasks to large commercial applications!

Hybrid pipe as well as tube benders are a terrific new tool for all kinds of metalworking tasks! They offer a variety of functions that make them the excellent selection for any task. One significant benefit is their flexibility; they can flex pipes and also tubes of differing sizes, shapes, and materials effortlessly. They likewise come with both hand-operated and also electronic controls, so you can obtain the specific angle you require each time. And also, these machines are exceptionally long lasting and also long-lasting - they won'' t corrosion or wear away over time!

An additional wonderful feature of hybrid pipe & & tube benders is their precision. With exact measurements, you can be sure that each curve will certainly turn out precisely as you intended it to. You can additionally change the speed settings to obtain simply the correct amount of pressure for each and every work. This makes them optimal for detailed bending tasks where precision is crucial.

Ultimately, these devices are unbelievably safe to use many thanks to their safety and security features such as protective guards and also guards. This lowers the threat of injury while working with this machinery substantially! And also, lots of versions come with an emergency situation shut-off switch in situation something goes wrong throughout procedure.

Generally, hybrid pipe & & tube benders have great deals of beneficial features that make them important for any kind of metalworking task! From their versatility to their safety functions, these devices supply individuals with whatever they need to complete any kind of job quickly and also properly (without compromising quality). So if you'' re trying to find a dependable machine that executes well every single time -then look no further than hybrid pipe & & tube benders!

Applications of Hybrid Pipe and also Tube Benders are a vital facet of manufacturing procedures. They can be made use of in the manufacturing of vehicle, aerospace, commercial, medical and several various other items. A hybrid bender (likewise called a combination bender) is a machine device that combines two benders into one unit for versatile bending operations. It enables drivers to flex both round and also square tubes with very little setup time and also no device altering called for! The flexibility provided by hybrid pipe benders makes them vital in all types of industries.

For instance, in the vehicle market, they can be used to make exhaust systems or framework parts. In the aerospace industry, they are utilized extensively in the manufacture of airplane wings or bodies. Within industrial applications, they have actually ended up being necessary for creating complex forms from tubing or pipelines for various purposes such as hydraulic lines or cooling systems. Also in medical applications, hybrid pipe benders play an essential role in generating customized prosthetics or orthotics!

Additionally(,) hybrid pipe benders are likewise commonly taken on within artistic sectors where their use allows craftsmen to produce distinct sculptures as well as attractive pieces out of steel tubes or pipelines. With these versatile machines at their disposal(,) artists can style complex shapes with accuracy and also simplicity which would certainly or else be difficult using conventional methods alone! Hybrid tube benders supply an unprecedented degree of flexibility to master artisan allowing them to discover their imagination even further.

Finally(,) it is clear that applications for Hybrid Pipe & & Tube Benders are plentiful throughout various industries due to their variety of capabilities! Their distinct ability to combine different flexing methods makes them indispensable tools for producing ingenious services with maximum effectiveness!

Hybrid Pipe & & Tube Benders are a terrific tool for collaborating with steel pipelines and tubes. Nonetheless, they require correct maintenance to keep them running efficiently! Here are some ideas to assist you look after your bender:

First, always inspect the device before use. Look for any type of signs of deterioration or harm that may have taken place in storage space or transportation. You need to additionally check all bolts to ensure they'' re tight and secure.(This will certainly aid stop accidents!)

Next off, it'' s vital to maintain the location around your bender tidy and without particles. This consists of products like scrap steel, tools, and other parts that can raise the risk of a mishap or cause damage to the device itself. Additionally, make sure to lube the moving components routinely according to manufacturer directions!

Finally, if something does fail with your bender, put on'' t attempt to repair it yourself! Instead, speak to a qualified service technician that is licensed in working with hybrid pipe & & tube benders. They'' ll be able to swiftly diagnose any type of problems and give you with advice on how ideal to proceed.

Overall, by adhering to these basic maintenance ideas for hybrid pipe & & tube benders you can make sure that your equipment remains secure and reliable for several years to find! Remember: excellent upkeep practices today can result in less troubles in the future - so wear'' t skimp on it!

Security Procedures when Working with Hybrid Pipe as well as Tube Benders

Dealing with hybrid pipe and also tube benders can be dangerous and so it is very important to adhere to all security treatments when utilizing them. Firstly, you need to always use safety eyeglasses, gloves, as well as clothing (specifically long pants) to shield yourself from any kind of flying triggers or particles that might be produced. Second of all, never run a bender without the appropriate training or guidance from a seasoned customer. Thirdly, make sure that there are no flammable products or liquids near the location of procedure as this can result in severe injury. Furthermore, make certain that all electrical cords are in excellent condition and also away from any water resources. Finally, never make use of a bender that is not in great functioning order as this can lead to significant accidents!

In addition (change phrase), before beginning work with a hybrid pipe and tube bender it is important to inspect the equipment for any indications of damage or wear-and-tear. Explore the advantages our Hybrid Pipe & Tube Benders can bring to your metal fabrication process. Contact our team in Hueytown, Alabama, today. With GSS Machinery, you're assured of superior machinery paired with exceptional customer service.. It'' s additionally necessary to look for loosened installations or busted components which could create a crash if made use of incorrectly. Furthermore, go through the supplier’& rsquo; s instructions carefully before usage; including set up information and security standards. Furthermore, constantly keep your hands free from moving steel pieces while operating the equipment; as these can promptly become extremely warm!

To conclude (transition expression), by taking these precautionary steps when dealing with hybrid pipe and tube benders you can substantially boost your security while executing these jobs. Remember: safety initially!

Hybrid pipe and tube benders are a terrific method to flex metal successfully. They are powerful tools, capable of developing intricate forms with precision. To conclude, these equipments are very effective as well as can conserve time and money on tasks that call for difficult bends! Not just do they have the ability to give excellent contours in a matter of seconds, but (they) likewise reduce labor costs by getting rid of manual tasks. In addition, making use of hybrid benders gets rid of the risk of human error which can cause expensive blunders! Hence, it is easy to see why so many people choose these devices for their flexing demands. All in all, hybrid pipe & & tube benders use an effective option for any metalworking task!

Furthermore, because of their adaptability and also benefit, hybrid benders are becoming increasingly prominent among enthusiasts as well. With marginal effort needed to run them properly, any individual can become competent at making use of one. In addition, when compared with various other kinds of flexing technology such as hydraulic or electric models, hybrids supply more cost without compromising high quality or efficiency. Consequently(,) it'' s not a surprise that this kind of equipment has actually come to be a best option for anyone searching for reliable flexing results.

In short, there is no doubt that hybrid pipe & & tube benders use incredible advantages over standard techniques of metalworking. From conserving both money and time to giving precision results with minimal initiative - they represent an ideal selection for practically any type of application requiring bends in steel tubes or pipelines! Without a doubt, when you think about all the advantages provided by hybrid benders - it'' s clear why they have become so extensively utilized today!

Tubes can be used for medical devices, which require a precise outer diameter. It is important to know the outside diameter because it indicates how much can be held as a stabilizing factor. The capacity of pipes is important because they are used to transport liquids or gases.

The electron tube is also known as a vacuum tube. It consists of a glass or metal-ceramic enclosed device that controls the flow of electrons in electronic circuitry.

Tube/pipe bending can be divided into four different types, each with a different level of complexity. You will encounter compression bending (also called rotary draw bending), roll bending (also known as mandrel tube bend), and roll bending with a mandrel.

Angles are typically 45 degrees or 90 degree. Pipe bends include all other offsets. The bends are usually made to the specifications of the pipe. Elbows, however, are standard prefabricated products that are readily available. Elbows have sharp corners, but bends do not.

The basic components are the mandrel, the clamp die, the pressure die, the wiper die and the bend die.